Services

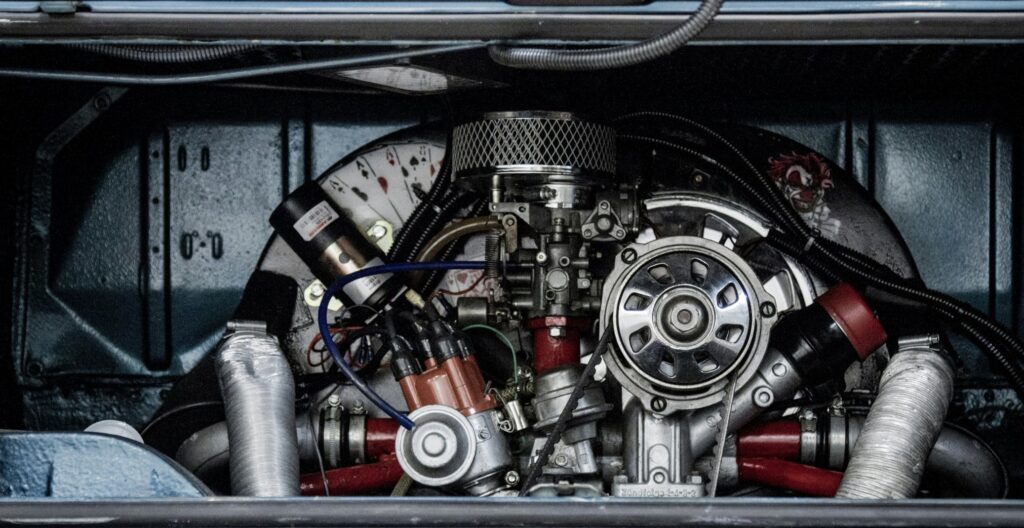

Precision Built

What We Offer

Prime Engine delivers top-quality engines by adhering to OEM specifications and assembling new and remanufactured parts with precision, thanks to our skilled tradesmen.

Trusted Brands

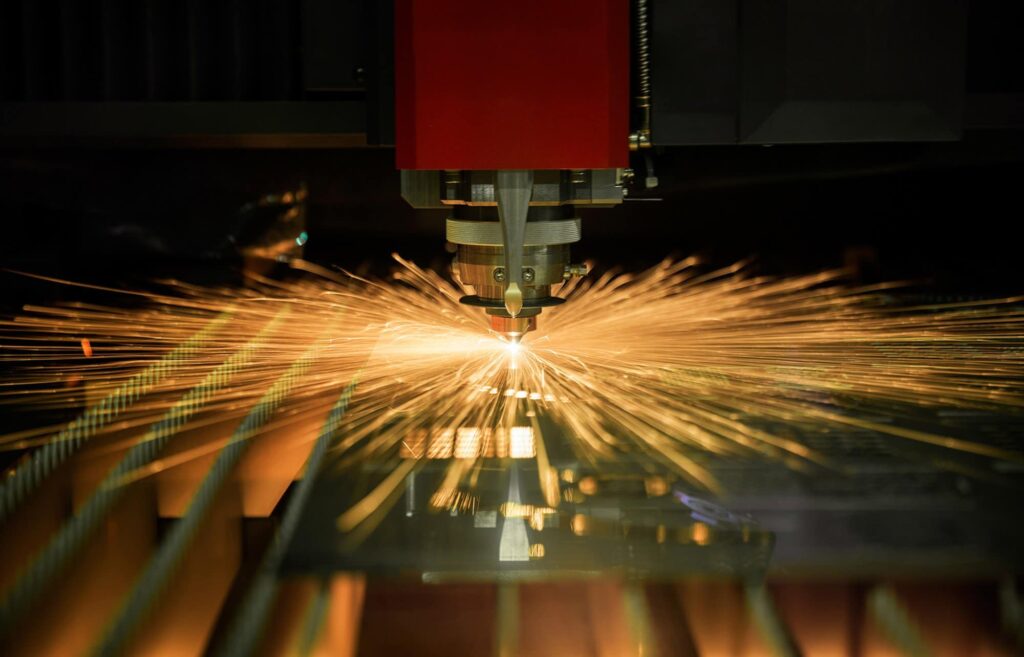

Premium Parts

We offer a wide selection of high quality parts for all your heavy equipment needs.

Prime Engine is a proud member of AERA

Prime Engine Remanufacturing Inc is an independent service facility and is not directly affiliated with KMP, Caterpillar, Waukesha, Pai, SBI, Cummins, Detroit, Mahle, Interstate-McBee, John Deere, FP Diesel, Volvo and Arrow.

Get in Touch

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

Hours

Today Closed